Flexographic printing is a popular method used for printing labels and flexible packaging materials. It is a versatile and cost-effective printing technique that involves the use of flexible relief plates made from rubber or photopolymer. These plates are mounted on rotating cylinders, which transfer ink to the substrate, creating high-quality prints.

Flexographic printing offers several advantages for labels and flexible packaging. It can handle a wide range of materials, including paper, film, foil, and various types of plastics. This makes it ideal for printing on materials used for packaging items such as food, beverages, cosmetics, and pharmaceuticals. The process is capable of producing vibrant colors, intricate designs, and fine details, making it suitable for creating eye-catching labels and attractive packaging.

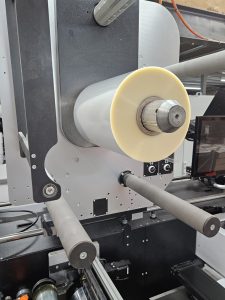

The Edale flexographic printing machine is a renowned name in the printing industry, known for its advanced features and capabilities. Edale is a leading manufacturer of flexographic printing presses, catering to the specific needs of label and flexible packaging printing. Some of the key capabilities and features of the Edale flexographic printing machine include:

- Precision Engineering: Edale machines are built with precision engineering to ensure high-quality prints. They are designed to minimise vibration and deliver consistent printing results.

- Multiple Colour Options: The Edale flexographic printing machine offers the capability to print in multiple colors, allowing for vibrant and visually appealing labels and packaging. It can handle various color combinations, including process colours (CMYK) and spot colours.

- Substrate Versatility: The machine is versatile and can handle a wide range of substrates, including papers, films, laminates, and flexible plastics. This flexibility enables printing on different materials used in labels and flexible packaging.

- Speed and Productivity: Edale machines are known for their high-speed capabilities, enabling efficient production. They can handle large print runs while maintaining accuracy and quality.

- Advanced Control Systems: The Edale flexographic printing machine incorporates advanced control systems for precise registration and color management. This ensures accurate printing and consistent colour reproduction across different print runs.

- Automation and Efficiency: The machine features automation options such as automatic tension control, web guiding, and in-line inspection systems. These features enhance productivity, reduce waste, and improve overall efficiency.

- Customisation Options: Edale machines can be customised to meet specific printing requirements. They can be equipped with additional modules and accessories for processes like die-cutting, varnishing, laminating, and foiling.

Flexographic printing is a versatile and cost-effective printing method for labels and flexible packaging. The Edale flexographic printing machine is a reliable and advanced solution known for its precision, substrate versatility, speed, automation capabilities, and customisation options. With its range of features, it enables high-quality printing and efficient production for a variety of label and flexible packaging applications.